Manual

Engine Booster Switch “Parallell Switch” → Located in aft stairs. It will separate the starting battery from the house. Set to “off” → Separates house from the starter. Set to “on” → All together. Use: To help start the engine! Caution: May damage other electronics. Engine Start Switch Located under the port bench in the…

LOA: 43.6 ft (13.30 m) LOA with bowsprit: 48.3 ft (14.70 m) LWL: 37.7 ft (11.50 m) Beam: 12.2 ft (3.70 m) Draught: 5.9 ft (1.80 m) Displacement: 17.0 tons Ballast: 5.5 tons Height of main mast over waterline: 56.5 ft (17.20 m) Height of craft on own cradle: 14.8 ft (4.50 m) Freeboard: Bow:…

LOA: 43.6 ft (13.30 m) LOA with bowsprit: 48.3 ft (14.70 m) Width: 12.3 ft (3.75 m) Height: 14.8 ft (4.50 m) Weight, cradle included: 18.00 tons Editor’s Notice The facts and figures given in this manual are subject to alterations without prior notice from Siltala Yachts. The manual is constantly being revised, and this…

Technical Data Type: Lehman Super 135 Cylinder volume: 6,220 cm³ Stroke: 115 mm Bore: 107 mm Number of cylinders: 6 Max. output: 94 kW / 43 RPS Power: 128 hp / 2600 RPM Continuous output: 79.4 kW / 41.6 RPS Power at 2400 RPM: 108 hp Maximum torque, overloaded: 280 lbf / 1600 RPM Injection…

Please study the enclosed Ford owner’s manual thoroughly. In the following, we have assembled the chief facts about maintenance and adjustments, adding our own experiences. We often refer to the manual and recommend you to make yourself familiar with it, especially the fault-finding chart. It may be very useful to know it well. As a…

The engine has a two-circuit cooling system, with a fresh water system circulating through the engine block, exhaust manifold, and expansion tank, and a sea water system. The sea water enters the boat through a sea cock and a sea water strainer on the starboard side of the engine, running through the priming pump (at…

The sea water pump impeller has to be replaced from time to time due to wear. Unscrew the lid, lift out the impeller by hand, or use a screwdriver to help it out. Install the new impeller and close the lid. The wings must be in the same direction! THE ENGINE ZINC ANODE CAN BE…

Engine Trouble To eliminate engine trouble, it is essential that the fuel is free from water, dirt, or other foreign bodies, i.e., completely clean. Our experience is that polluted fuel causes the greater part of all engine trouble; therefore, we recommend you always filter the fuel when refilling and frequently check the water separator, located…

The maintenance of the lubricating system is of utmost importance. Good care makes your engine last longer and saves you trouble. The engine is pressure-lubricated with a camshaft-driven lubricating pump, which feeds oil to the bearings and other lubricating points. The system has a built-in main-flow filter through which the oil passes. Technical Specification Oil…

Make sure that there is sufficient fuel in both tanks. Should one of the tanks be empty, close the fuel tap. Check the water separator. If dirty, drain. If the fuel lift pump priming lever is in an upper position, turn the engine 1/4 turn with the starter motor while pushing the stop button. This…

Make sure that the main switch (located on the steering console) is in position 1 or 2. (Ford manual p.11, fig.2) Check engine oil, water level, and battery water level. Check that both throttle-gear remote controls are in neutral. This is important because the starting circuit is equipped with a current restrictor, which is not…

A Borg-Warner 10-18-008 2.1:1 gearbox with a reduction gear is fixed to the flywheel housing of the engine. Technical Specification Type: Borg-Warner Velvet Drive (10-18-008) Reduction gear: 2.1:1 Direction of rotation: Left (viewed from stern) Oil capacity: 1.7 litres (without oil cooler) Oil type: BP Automatic Transmission Fluid, Type A-DX Esso Automatic Transmission Fluid, Type…

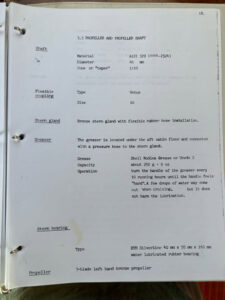

Shaft Material: AISI 329 (cont.2324) Diameter: 40 mm Cone or “taper”: 1:10 Flexible Coupling Type: Vetus Size: 10 Stern Gland Bronze stern gland with flexible rubber hose installation. Greaser Grease: Shell Rodina Grease or Unedo 2 Capacity: about 250 g = 9 oz Operation: Turn the handle of the greaser every 10 running hours until…

A Teleflex/Capilano hydraulic steering system, consisting of the following units, is standard: Steering pump (wheelhouse) – Capilano 275 Steering pump (poop deck) – Capilano 275 Uniflow connection valve – Uniflow 50 Rudder cylinder – Teleflex Ba 200/7 Tm Oil Filling We advise you to check the oil level from time to time (once a month)…

When you move the lever, you can feel three positions: Upright is neutral, forward is forward, and backward is reverse. There is a 10° sector where the lever does not affect engine revolutions. In this position, the engine is on idle, about 700 RPM. Idle Position The gear is released by pulling the lever to…

BATTERIES The boat is equipped with 2 x 12 V/200 AH batteries. The batteries are installed in the engine room and parallel coupled (12 V = 400 AH). Extra batteries can be fitted. An alternate battery current switch is located in the steering console. The switch has the following positions: 0 = Off, except the…

The alternator is fitted on the port side of the engine (MOTOROLA 14V/70A). It has a built-in voltage regulator. The charging power is divided to the batteries according to their respective charging levels. Both batteries are always being charged, no matter which position the switch is in. The charging passes through a blocking diode system.…

Use a 12 V lamp connected to a three-foot piece of twin conductor cable or some other similar device. Checking the cables with this instrument shows how far the current passes, and the defect can easily be located. The most common fault is corrosion or poor connections. Deck sockets and fittings should be coated with…

ZINC ANODES drawing: zinc anode plan The electric system and the engine and fuel tanks are earthed through the zinc anode, located on the exterior hull, next to the propeller. This device discharges the static electricity of the boat, thus preventing electrolysis from taking place on the propeller shaft and other underwater metal parts. If…

The masts are made of aluminum, with stainless steel fittings and stainless steel standing rigging and halyards. The sails are of high-class terylene. In normal use, the following points should be kept in mind: UV rays may damage sails exposed to strong sunshine. Use boom covers, but remember to dry the sails as soon as…

Bilge Pump A standard boat is equipped with an electric centrifugal bilge pump with a capacity of about 40 litres (9 gallons) a minute. The pump works either manually or automatically, controlled by means of a “man/autom” switch on the switch panel. The manual position is spring-loaded and will cut off the current as soon…

A standard boat has the following submerged through-hull fittings: Fore toilet inlet Fore toilet outlet Fore toilet wash basin outlet Sink outlet Engine salt water intake Aft toilet intake Aft toilet outlet Aft wash basin outlet Through hull fittings of the options: Salt water system inlet Septic tank outlet The following through hull fittings, which…

The wheelhouse has been designed to function as the center of all maneuvering and navigation, with the exception of sheet and rig handling. Thus, the helmsman has easy access to and control over the wheel and throttle, gear lever, gauges, compass, switch panel, echo-sounder and sumlog dials, chart-table with lamp, and optional autopilot panel, VHF-radio,…

The galley has been designed to be roomy enough for the cook, yet permitting action with a minimum of moving about, in port as well as offshore. If cooking is intended in rough conditions, it is advisable to install a support-belt to give the cook both hands free. Equipment Double basined sink with cover hatch…

Fresh Water Tank The tank, made out of polyethene plastic and taking 250 litres (55 GB, 65 US gallons), is situated under the saloon floor, accessible through hatches. Clean the tank and check the water level through the twist cap on the tank. The tank filler is on deck, on the port side, marked “Water.”…

Regulate the flame with the regulator knob: Big flame right, small flame left. Turning the water control knob counterclockwise increases the water amount, and turning clockwise decreases it. The most economical positions are: flame in the middle and water amount small. If you use the shower, both flame and water amount should be at maximum.…

The water pressure system is operated by a belt-driven, automatic diaphragm pump, controlled by a built-in pressure switch which turns the pump on when the pressure is lower than 1.5 kPa/cm² and off at 2.2 kPa/cm². If the pressure of the water system fails, when the “fresh water” knob on the control panel is pulled…

WC Operation Both toilet compartments are fitted with a Lavac water closet. It works on the suction principle and therefore it is very important that the seals of the lid and the seat are clean. The system does not work if the lid or the ring is broken. There is about 1 litre (¼ gallon)…

IMPORTANT If the boat is fitted with a septic tank (made out of acidproof steel) there is a 3-way cock next to the bowl, which selects emptying either into the tank or the sea. The tank is large enough for about 20 operations. When on the open sea the tank can be emptied with a…

The air heating unit, an Eberspricher, is located under the port side deck, accessible from the wheelhouse. The control switch is on the wheelhouse inside wall, port side. The exhaust pipe is led through the port topside, beneath the steps to the poop deck. It has a rubber plug, attached to a chain. The rubber…

The gas system of a standard boat comprises the following parts: 1. Gas bottle storage on aft deck, containing a gas bottle with a shut-off valve and flexible hose connected to the gas piping. The gas bottle storage is ventilated through the topside. 2. The gas piping is made of 10/12 mm copper, running unbroken…

HOW TO USE THE MACHINERY By and by you will learn that there is a certain speed range where the engine “feels” right, due to its specific vibration. With the comfort of the engine and the crew in mind we recommend speeds between 1750-1950 RPM. RPM Speed (knots) Fuel consumption/h (litres) Fuel consumption/h (GB gal)…

A NAUTICAT motorsailer has two steering stations with remote controls to permit steering outside as well as inside. One thing to remember about the remote control is always to return the lever into neutral when changing from one steering point to another. If one remote control is engaged, the other one won’t work. This may…

The wind direction dictates the order in which the mooring lines should be fastened. If the wind is on the bow, attach the bow first, if it is on the stern, the stern first. Loose line ends should, according to good seamanship, be gathered on board, not on the pier. If you have to change…

Aided by the coefficients one can use the distance recorder and the log pretty safely. Unless having made up this table, do not trust the accuracy of these instruments. Try, if possible, to use one and the same measured distance, and remember that the longer the distance and the more carefully you measure it on…

The NAUTICATs are motorsailers, differing from pure sailing yachts chiefly in the greater emphasis on comfort and roominess, and in being equipped with a more powerful engine. Thus the hull shape is slightly more bulky, the displacement a bit greater and the sail area somewhat smaller. This naturally affects the sailing performance to a certain…

When running downwind, attach the kicking strap to the cap shroud, to avoid the risk of unintentional gybing, i.e. when the boom slams over from one side to the other. This may carry away your entire rig, if the wind is strong enough. When running, try to sail “butterfly” i.e. “wing and wing”, or to…

When tacking in light winds with a NAUTICAT you may have to help her turn by releasing the genoa only when you have gained the new tack. I.e., do not loosen the genoa sheet before the turn, but after. The wind on the “back” side of the genoa will make the bow fall downwind, and…

When hoisting, blanket the spin with the genoa. Hang the spin pole on its hook, fasten lift and downhaul, and pull them tight, adjusting the pole into horizontal. The spin pole should be on the windward side of all the forestays, i.e. the opposite side in relation to the main boom. Fasten the spin bag…

NAUTICATS previously used, as well as new ones. Before launching, check the following: Oil levels of the engine and gear-box Engine fresh cooling water level Sea water cooling system, the pump impeller in its proper place, draining taps closed, hose connections tight. Fuel system water separator (“water trap filter”) free from water (ch. 3.2.1) That…

The rig can be adjusted into various mast angles and mast bends, according to the characteristics of the sail. We gave you some basic advice as to sail trimming in the sailing chapter, but in order not to make these pages swell out too much, we kindly ask you to consult a suitable guide book…

Bleed and start the engine (ch.3.1.4 and 3.1.5), and check the following: Engine oil pressure: 3.5-4.0 kp/cm² (50-60 lbf/in²) Gearbox oil pressure: 7.5-9.6 kp/cm² (105-135 lbf/in²) That the ampere meter indicates charging That the voltage gauge dial reading is 13.8 That the charging warning light goes out That the sea cooling water flows, i.e., that…

The gelcoat used on NAUTICATs will not fade in the sun or by age. However, to achieve maximum durability, the hull needs maintenance. Make sure that there is no sand, or other abrasive substance on the hull, by gently brushing it off with a dry cloth. Then clean with warm water and detergent, using either…

Exterior teak The treatment depends on whether you want the teak to remain dark or become light, “grey”. If a dark tinge is desired, oil the wood from time to time, using either normal teak oil, or special water resistant cleaning/brightening liquids. Before applying the oil, clean the wood with mild detergent to avoid scrubbing…

HAULING OUT The yacht can be hauled either with a cradle on tracks, or by lifting with a crane. If using a crane, observe the same cautions as when launching (drawing “docking plan and cradle”). When applying the slings, make sure they won’t rest on the propeller shaft. CRADLE Preferably store your NAUTICAT in her…

drain the fresh water tank/tanks by running the PAR pump all taps open. When the pump sucks air, undo the hose at the pump outlet, and empty the upper part of the plumbing system by blowing strongly. Dry the water tanks and leave the caps open. drain the optional sea water system by running the…

Halyards: Check that shackles, wires, ropes, and particularly the rope-wire joints are OK. Replace any part which may not be strong enough. Check the halyard sheaves in the mast head. They should rotate freely. Corrosion between mast and steel parts Stainless steel halyards, stays, and shrouds cause corrosion when in contact with aluminium. Therefore store…